— From Carbon-Reduction Design to the Practice of Sustainability

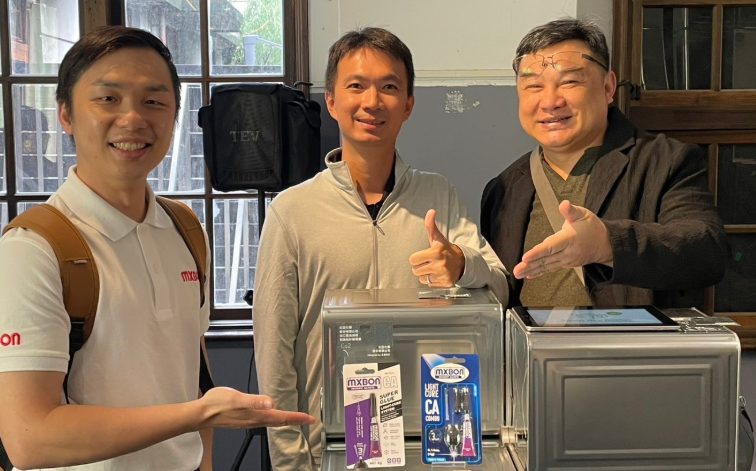

In response to the global trend toward net-zero carbon emissions and the government’s “Industrial Low-Carbon Packaging Support Program,” Cartell Chemical Co., Ltd., as a leading brand in the Asian adhesive industry, showcased the results of its packaging sustainability transformation on Monday, October 27. At the export low-carbon design project results presentation, the company introduced FSC-certified paperboard and soy-based ink blister packaging, replacing conventional plastic blister packs and PET plastic jars.

This project was advanced under the support of the Taiwan External Trade Development Council (TAITRA) “Low-Carbon Packaging Design Guidance Program,” and executed together with Artist Design Co., Ltd. The initiative completed a packaging optimization and carbon footprint analysis for a consumer product series, marking a new design-driven chapter in green carbon reduction for the chemical manufacturing industry. The results were displayed in the Taiwan Design Research Institute’s “(Re):P—Packing Lab” low-carbon packaging exhibition (Oct 27 – Nov 16), demonstrating Cartell’s concrete achievements in applying green design to industrial sustainability.

“For us at Cartell Chemical, carbon-reduction is not a mere slogan — it is a revolution of industrial responsibility,” said General Manager Mr. Chen Ying-Hsien. “As a pioneer in the Asian adhesives sector, we chose the most challenging path — starting with supply-chain and packaging innovation — so that every single tube of glue becomes the starting point of low-carbon action. We prove with data that design can reduce carbon, innovation can change the environment, and sustainability can become a competitiveness.”

1. Data-Driven Packaging Carbon-Reduction Results

Cartell Chemical completed comparative carbon-footprint calculations in 2025 for two primary product-packaging categories, both showing notable reductions in CO₂ emissions:

- Instant-glue hanging-card packaging: After introducing standardized paper blister packaging, the carbon footprint was reduced by approximately 49.9% compared to traditional plastic blister packaging.

- 25-unit bulk pack: By replacing PET plastic jars with FSC-certified paperboard packaging, the carbon footprint dropped by about 94.7 %, showing a very high degree of environmental improvement.

Note: The calculations are based on “each product item = 1,000 sets” as the baseline. Both the hanging-card and bulk-pack categories exhibited significant carbon reduction. Based on the company’s actual annual production scale (several million sets), the overall potential annual carbon-emission reduction could reach tens to hundreds of tonnes CO₂e — equivalent to the carbon-sequestration effect of planting over 2,000 trees — offering tangible and long-term environmental benefit.

2. Cross-Disciplinary Design Collaboration × Scientific Carbon-Footprint Audit

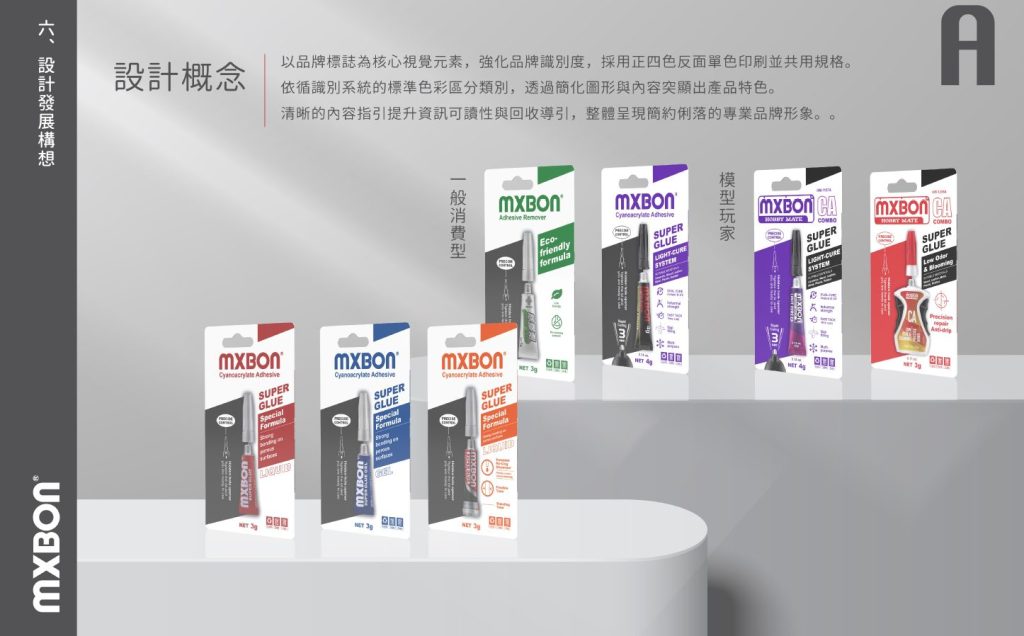

To ensure that the design results combine aesthetics and functionality, Cartell Chemical partnered with Taichung Artist Design to optimise the packaging visual appearance, internal structure, and material thickness. Concurrently, following TAITRA’s guidance, the company introduced a carbon-footprint methodology, calculating full-chain emissions using “area → weight → emission coefficient,” thus establishing a complete carbon-footprint data foundation and laying groundwork for future Life-Cycle Assessment (LCA) verification.

Through simplification of the packaging structure, minimisation of printed surface, and substitution of plastic with paper materials, Cartell transformed traditional high-carbon packaging into a green packaging solution with recyclability and regeneration in mind.

3. Commercial Production Launch in Q1 2026

Cartell Chemical plans to officially introduce the paper-blister packaging into its production line in the first quarter of 2026. The first wave will roll out at its MXBON® consumer instant-glue product series, gradually replacing existing plastic-blister packaging.

This initiative not only aligns with Taiwan’s Ministry of Environment “Green Design Policy” and the Ministry of Economic Affairs “Industrial Net-Zero Action Plan,” but also offers global OEM/ODM clients adhesive products that comply with international sustainability standards.

4. Leading the Industry in Carbon-Reduction Practices

Cartell Chemical has long committed to adhesive technology innovation and sustainable R&D. In recent years, it has also advanced green packaging materials, eco-friendly inks, and packaging carbon-footprint system management. Looking forward, the company will continue to promote three core goals:

- Low-Carbon Materials – Adopt full traceability and low-carbon FSC-certified paper materials.

- Packaging Circularity – Optimise standard packaging structures to improve packaging recycling and reuse efficiency.

- Smart Manufacturing – Integrate automated processes and environmental-management data to make carbon footprints visible and manageable.

Free Design Showcase — You’re Invited!

- Exhibition Name: (Re):P – Packing Lab

- Dates: 2025.10.27 (Mon) – 11.16 (Sun)

- Time: 10:00 – 18:00 (Closed Mondays)

- Location: Taiwan Design Museum 01 Exhibition Hall, Songshan Creative Park (West-Facing Tobacco Factory 1F)

- Address: No. 133 Guangfu S. Rd., Xinyi District, Taipei 110, Taiwan

We sincerely invite industry partners, channel clients, and media friends to visit and witness Cartell Chemical’s innovative practices in low-carbon packaging design, and to understand how the chemical-manufacturing industry can apply green-design thinking to actualise sustainable transformation.

About Cartell Chemical Co., Ltd.

Founded in 1994, Cartell Chemical is Asia’s leading manufacturer of instant adhesives and industrial adhesives under the brand MXBON®, marketed in over 100 countries worldwide. With the philosophy of “We’re joining more than materials — we’re joining trust among people and society,” the company actively promotes green R&D and sustainable manufacturing, and continues to lead the adhesive industry toward a low-carbon future.